Construction of the Geelong Refinery was a massive effort spanning three years, costing £20 million and employing over 1000 construction workers from Australia and around the world. Today it employs 700 people and provides Australia with more than 10 per cent of its fuel – and supplies Victoria with more than 50 per cent.

Getting started

The Geelong Refinery stands testament to one of the most vital growth eras in Australian history – and yet it was almost mothballed before it even started.

The refinery, which ushered in powerful economic, social and ethnic changes during the post-war 1950s, was originally meant to be a bitumen and lubricants plant, not a petroleum refinery.

In fact, its proponents, Shell, knocked the initial idea on the head when it learned world market expectations for MVI lubricating oil had been seriously overestimated.

Other factors, including fears of oil-producing countries nationalising the industry – as had happened in Russia and Mexico – gave the Geelong Refinery plans new life. Combined with government defence concerns, economic foreign exchange savings and the demand for more jobs, the plant was revived.

Railway and underpass construction on Refinery Road at Corio.

Railway and underpass construction on Refinery Road at Corio.

Building the main tanker wharf that will service the refinery.

Building the main tanker wharf that will service the refinery.

Bringing a small town to life

Like the Snowy Mountains Hydro-electric Scheme, the Geelong Refinery drew heavily on labour from European migrants seeking new lives after the horrors and destruction of World War II.

A thousand workers arrived from Holland, Italy, Lithuania, Latvia, Britain, and France – a total of 14 European countries – to work on the construction project. Many of these men wouldn’t see their families, who were still overseas, for at least another two years.

The £20-million project that unfolded at Geelong was extraordinary. It transformed the Corio site, formerly a little-used paddock with ready road, rail and sea access. Construction took three years, from 1951 to opening day on 18 March 1954.

200 ships brought in project materials, while then the largest crane in the Southern Hemisphere, at 64.5 metres, was used to swing 30-tonne sections into place. The country’s longest oil pipeline was also built to carry thousands of gallons almost 60 kilometres to Melbourne from oil fields in Bass Strait.

A hostel was initially built to accommodate the refinery workers. 175,000 yards of earth was then moved and a 90-acre housing scheme constructed to house the workers. The streets in the Shell housing estate, within the suburb of Corio, were named after different kinds of seashells, such as Rotella Avenue, Rimula Road and Teleta Crescent.

Workers constructing a 36-mile pipeline between the Corio refinery and Newport.

The impact on the Australian landscape

The refinery’s all-important distillation unit, furnaces, boiler houses, tanks, a wharf, pump stations, warehouses, offices and workshops were all built during this time. The project was enormous: an economic and social game changer.

More than 60 years on, the Geelong Refinery today remains a vital contributor to Australia’s energy needs and a key employer.

Its operations are bolstered by ongoing environmental initiatives. It remains a strong ongoing contributor to the community. The future looks set to provide opportunities for both the refinery and its broad family of employees.

For a refinery that almost failed to get off the ground, it’s a remarkable testament to determination and diligence, to confidence and community, and to achievement.

No smoking: Safety first at the crude distilling unit.

No smoking: Safety first at the crude distilling unit.

A worker stands surrounded by metal on the first level of the three-level refinery structure.

A worker stands surrounded by metal on the first level of the three-level refinery structure.

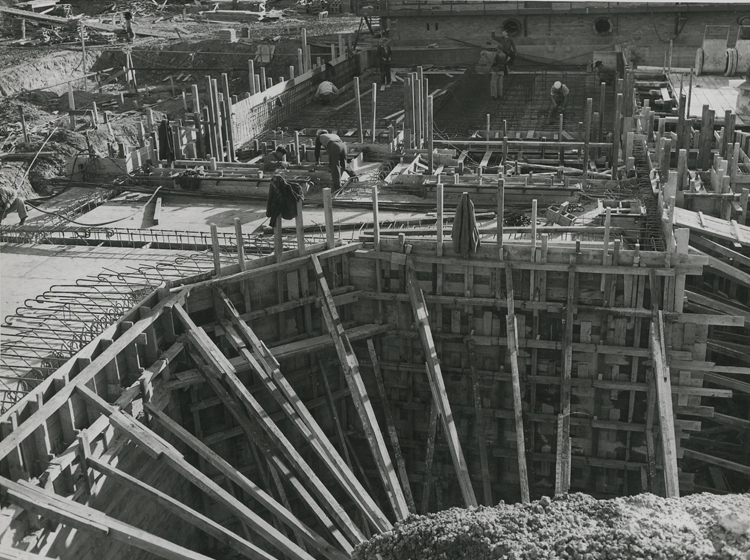

Constructing the saltwater intake and channel at the refinery.

Constructing the saltwater intake and channel at the refinery.

The crude oil distilling unit under construction at Corio.

The crude oil distilling unit under construction at Corio.

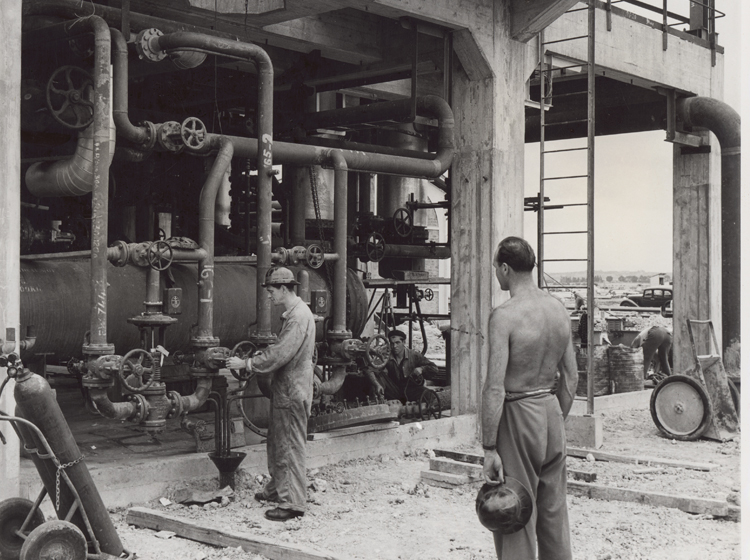

Working in the heat on the refinery’s crude distilling unit.

Working in the heat on the refinery’s crude distilling unit.

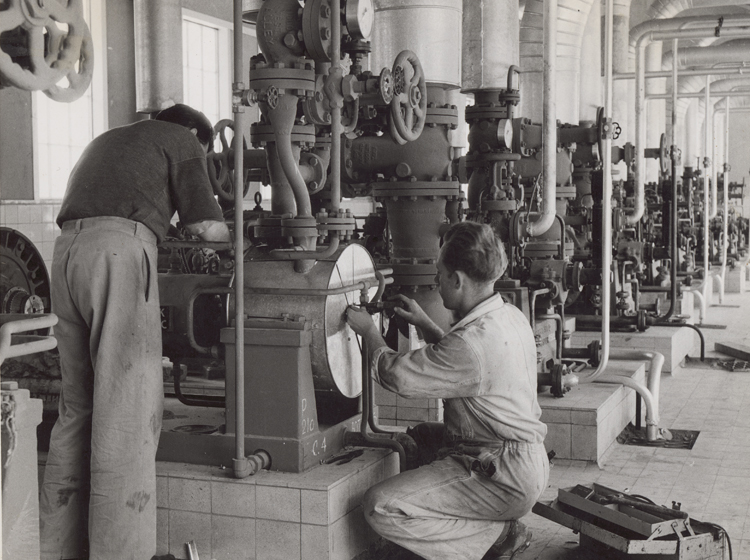

Keeping cool: Insulating a pump in the distilling unit.

Keeping cool: Insulating a pump in the distilling unit.

Shell Geelong Oil Refinery 'On Stream' 1954

Shell Refinery: 50 Years in Geelong (history book) - chapters 1 and 2 (provided by Viva Energy)

Go Well - 100 years of Shell in Australia (ISBN 0 949905 69 0) (images of relevant pages uploaded to CQ as files)

http://www.geelongadvertiser.com.au/news/geelong/fine-man-fine-solder-the-story-of-norlanes-namesake/news-story/929f72a6c0beb12787e6cc0618fdb67a

Interested in learning more about the Geelong Refinery?

Find out more here